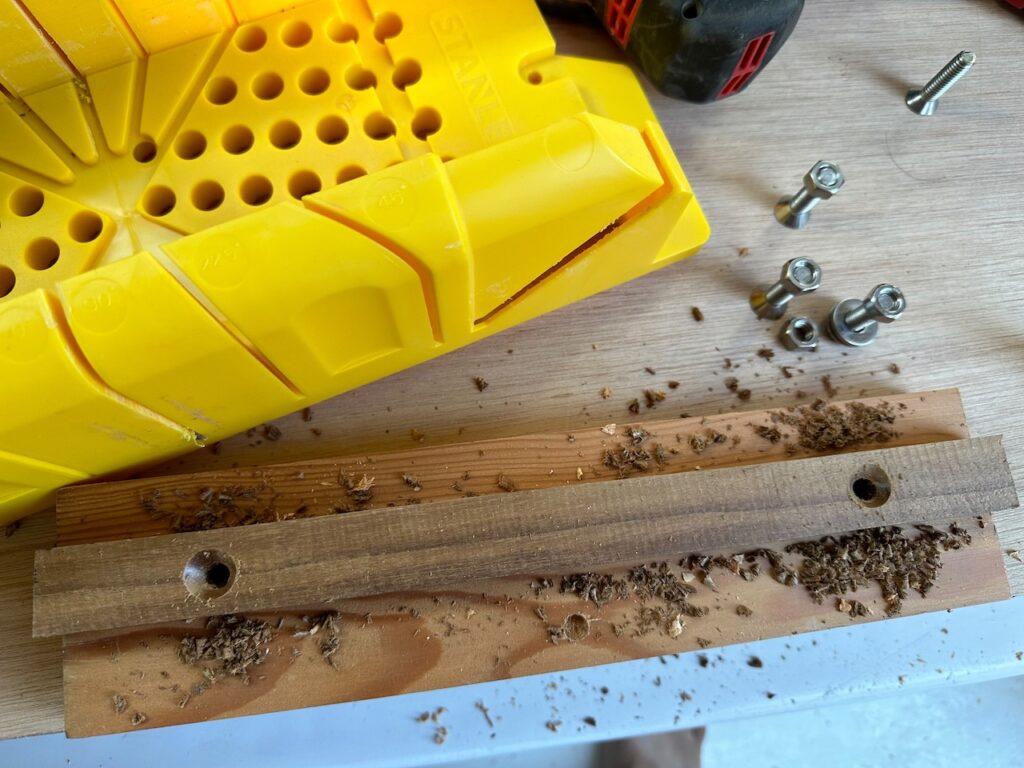

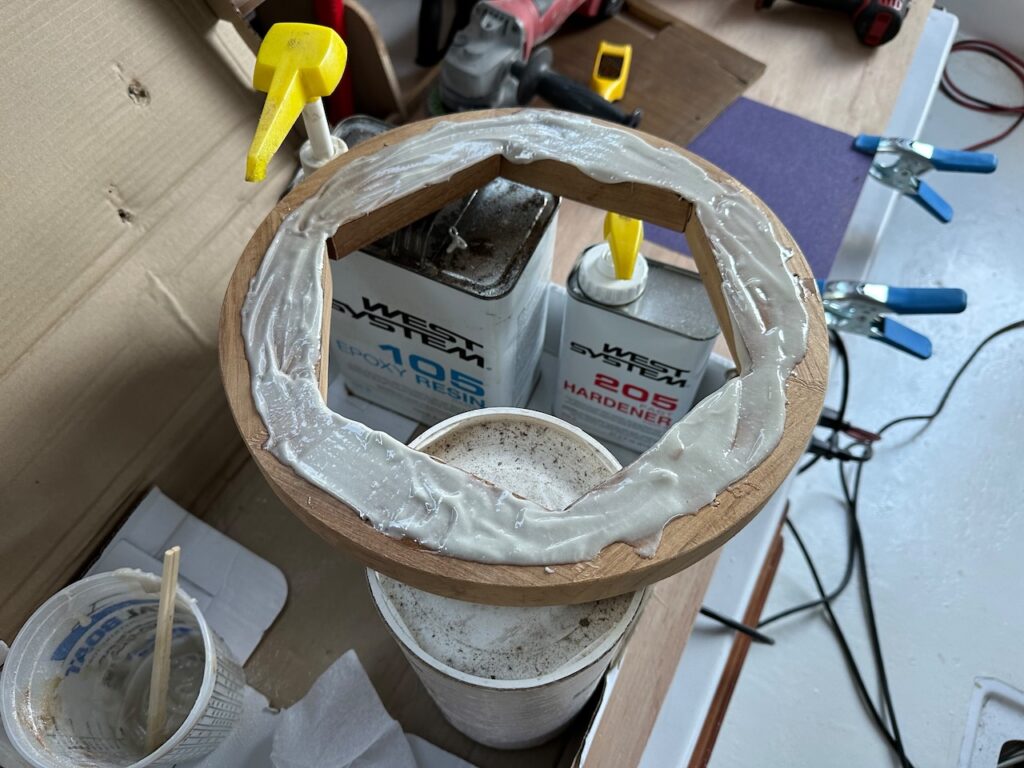

Started making a new shelf for v-birth with a few guides to keep it in place. Running out of 3/4″ ply so had to join a few remaining odd pieces together.

Thinking it will have a cushion with magnetic attachments so it can be used both as a middle cushion and as a tray to put a drink on.