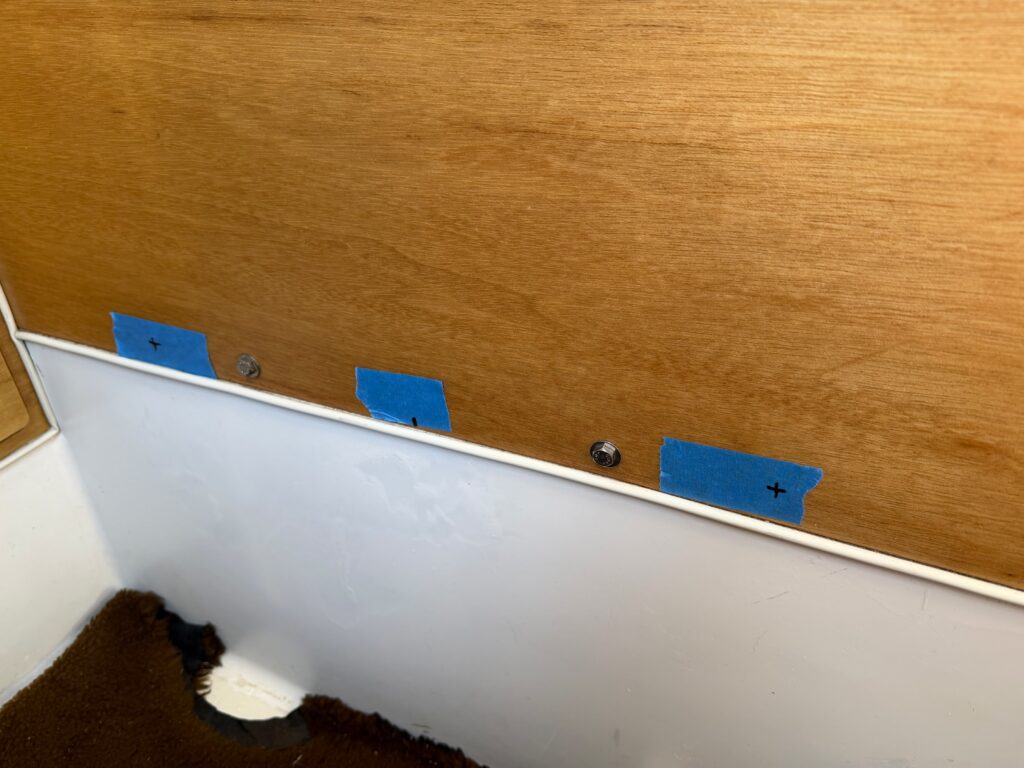

After all the wiring was done and working last year, I had to disconnect the system to organize wires better and get them away from rotating parts. Of course, once things reconnected, the BMS refused to work properly – not seeing batteries, not turning on the distributor, etc. Tried a lot of troubleshooting with no success.

I took it back to local distributor where they ran some bench tests and confirmed it was working OK. With holidays and travel getting in the way, I finally picked it up and brought back to the boat this weekend.

Plugged it back into the system and it still didn’t power up. It did ask to update firmware, which I promptly took care of. As soon as it booted up with the new firmware, we were back in business – everything working nominally! I did a happy dance. One big TODO for this year can be checked off. Next up – tackling that remaining vibration in the shaft.