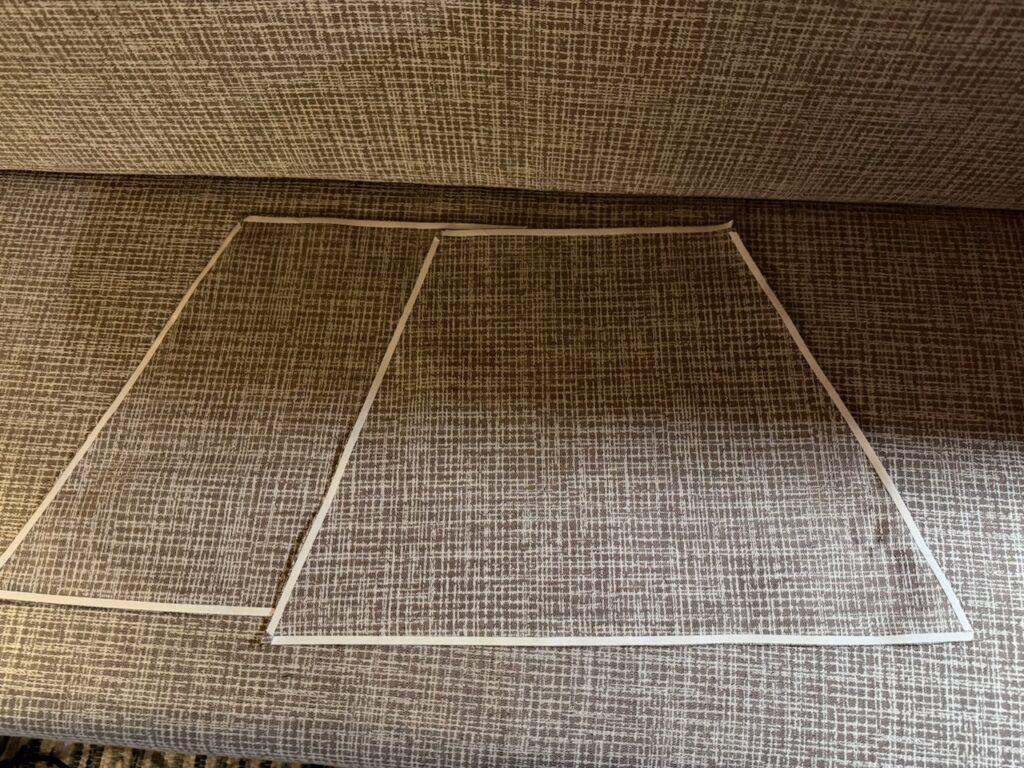

Started working on the headliner for v-birth. My original plan was to use template material to create proper shape with all the cutouts required and then transfer it to the headliner material. That proved to be almost impossible. The template kept shifting around and the holes and edges ultimately didn’t match that well.

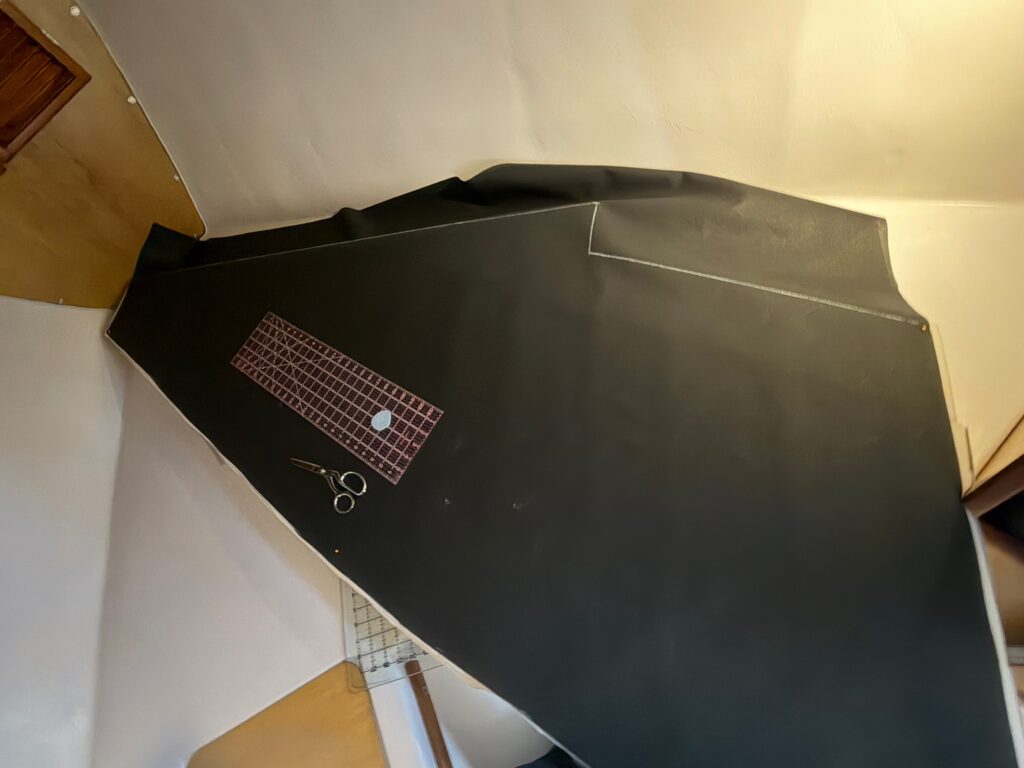

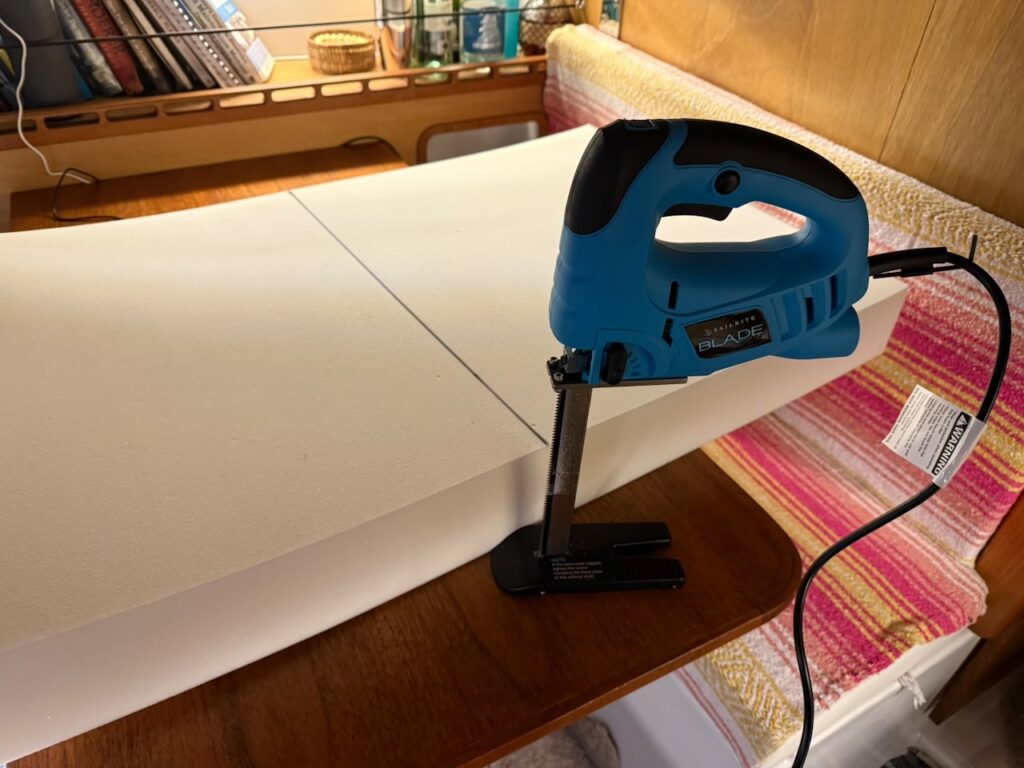

So I changed the approach and cut out the rough shape directly in the headliner material, then glued the part that didn’t need much adjustment (e.g. the center), and then slowly worked around the edges: drawing the lines, trimming in place, gluing. That worked much better but was a bitch to do upside down in a cramped space. Boat yoga to the max.

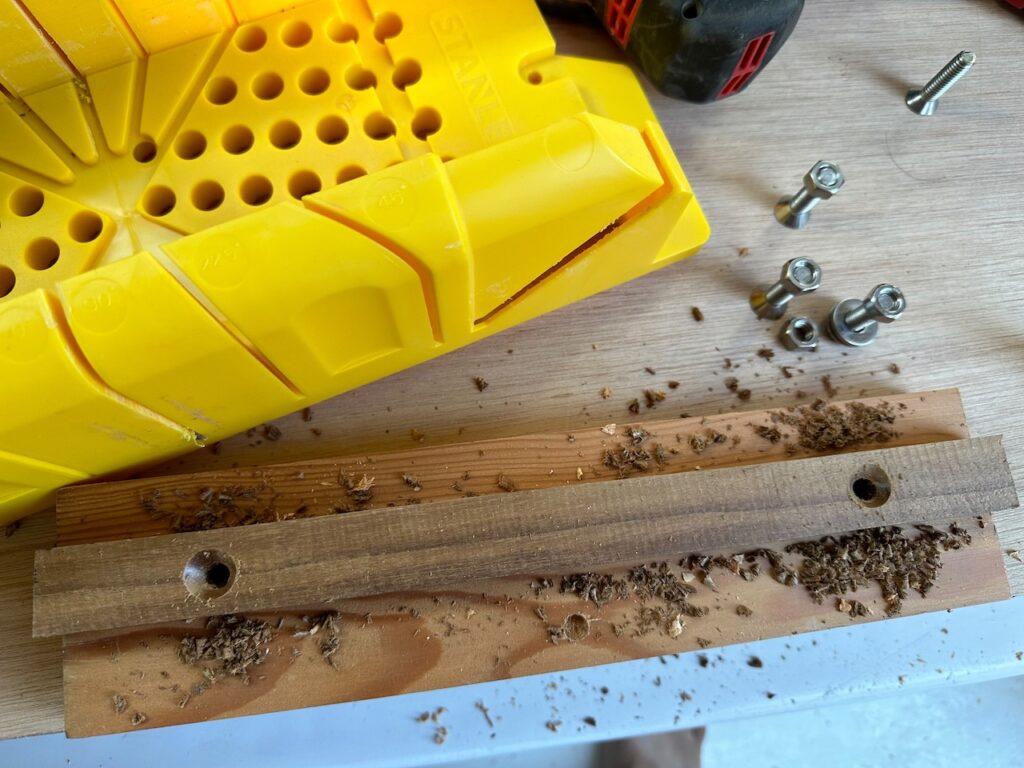

The final challenge was to figure out what to do with the visible edge, especially around the hatch. The foam backing, even though it’s thin, is yellow and visible on the edge and that looked kinda ugly. I tried sewing a strip of nylon on but after an hour of experimenting couldn’t get consistent results that looked good. Then I tried to glue that nylon; also without success. The final approach I settled on was to remove about 1/2″ of foam at the edge and glue that edge flash. Turned out OK.