Found a few slow leaks on the rudder post and realized the cover plate was never attached after being painted in 2017. Took time to clean it up, seal it properly, and add fasteners. Should be nice and dry now.

1971 Newport 30 Sailboat

The time has come to bring the stairs up to new standard. The bastard painters I hired back in 2017 painted the tops of steps with nonskid exterior paint (for the interior stairs!). And of course that is exactly where beautiful teak is supposed to go. Had to be fixed.

Started by sanding down that crap

After spray-painting the sanded stairs back to uniform white, I turned my attention to teak, which was sanded, stained, and varnished

Then, the teak was mounted with bungs and final coat of varnish added on top.

Finally, I put in two new latches to secure the steps in place.

Super happy with the result!

PSS needs to have its bellow replaced every 6 years. The time was up for mine and with motor and batteries removed, I had clear access.

Almost every page of the PSS replacement kit said “do not do this with boat in the water” but plenty of YouTube videos showed that it actually could be done so I decided to use the opportunity.

That task is not for the faint of heart. Water was gushing in and took some time to property secure the new seal. All in all, the task was completed and I learned quite a bit.

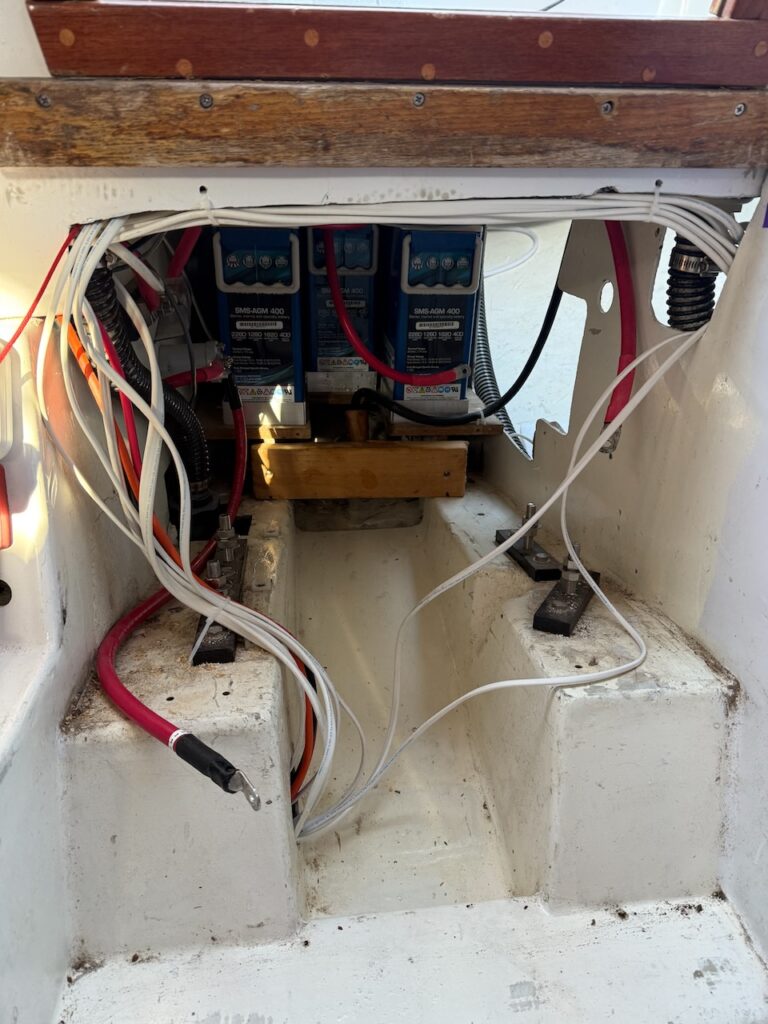

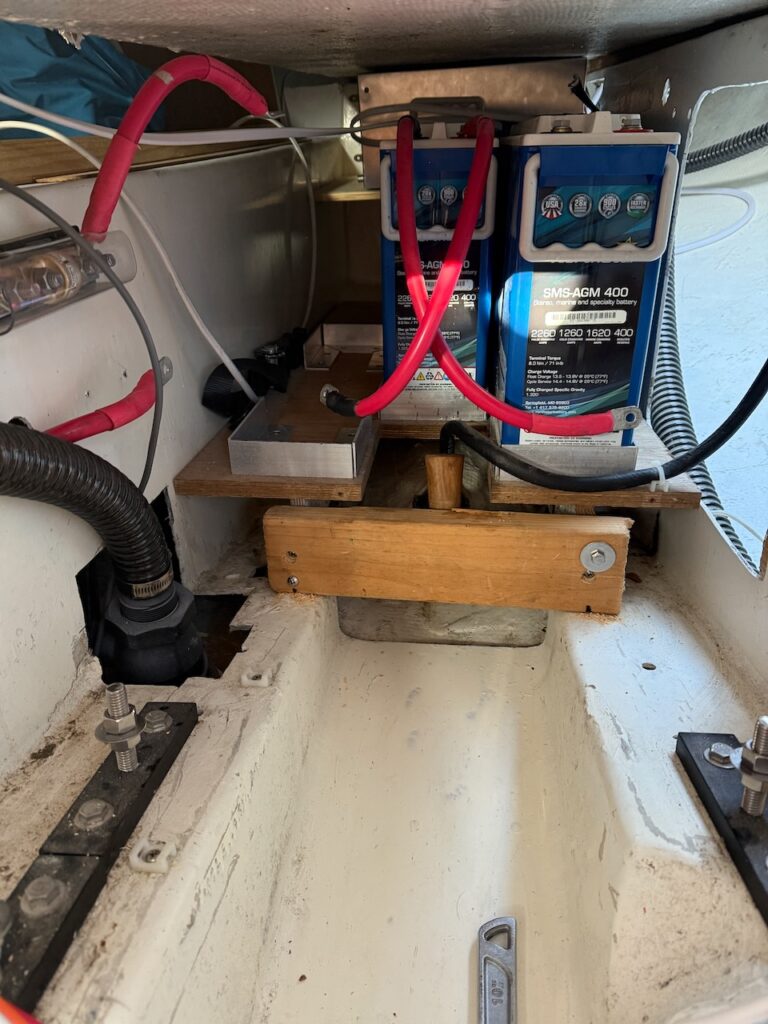

In preparation for the new Victron batteries and other components, per plan, I took time to clear out the engine bay. Had to put in a piece of 2×4 to keep PSS bellows pressurized and avoid sinking the boat.

With my friend Viktar helping, I have a second pair of hands to help get up the mast and fix a few things: main sail track, foredeck light, and spreaders. I set up the harness not the main halyard and used spinnaker halyard for a bag of tools & parts and a bucket of soapy water with a sponge.

Task 1 was to just clean the underside of spreaders that have accumulated some green growth

Task 2 was to replace the bulb in the foredeck light. Unfortunately, the bulbs I had in my bag didn’t match the light. Same brand, same model but 10 years difference. Need to order another bulb and get up there again.

Task 3 was to get down the small piece of track at the top of the mast to secure it to the rest of the track. When my rigger installed it originally, he ordered it too short and then proceeded to add a small piece and push it all the way up the mast without connecting them. With full main up and some good wind, that small piece rides up exposing a gap and mainsail cars slip out. After every sail without a reef in, I have to remove and reinstall the mainsail into the track. Royal pain and bad vibes to the rigger.

After getting to the top, I pushed the small piece down and secured both sides with stainless straps. They don’t need to carry lots of load, just to not let that small piece ride back up. Will need to test this out on the next sail.

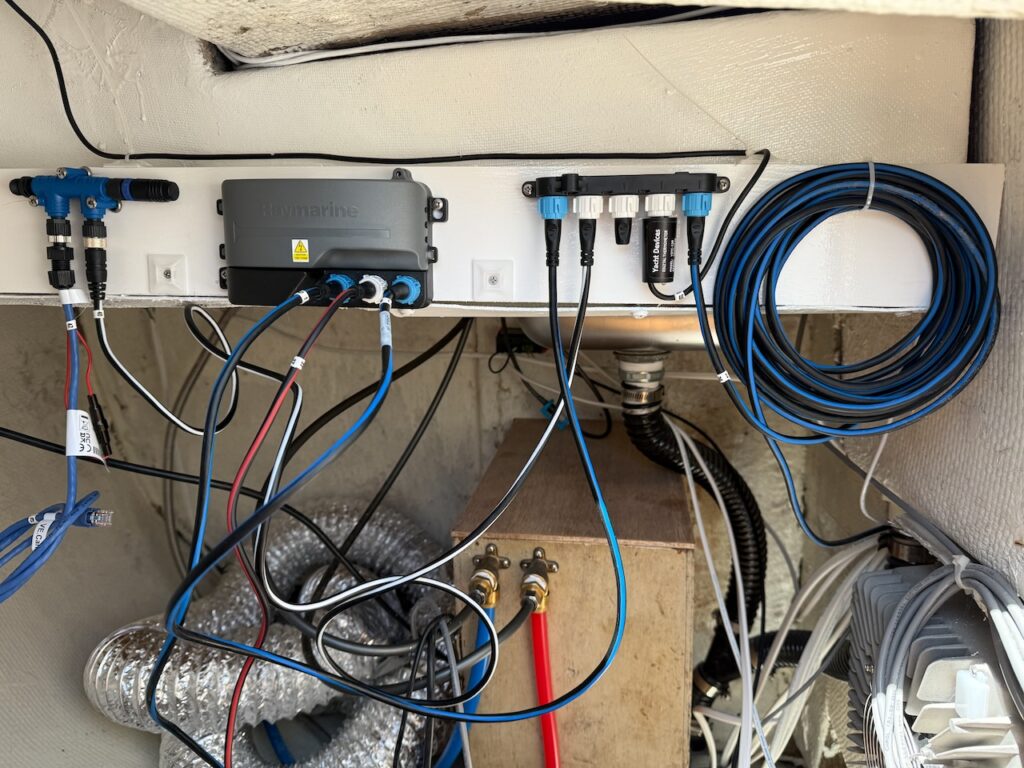

Continuing to move forward with the instruments plan. Installed a backing board and painted it with basic white bilge paint. Then mounted all the connectors for both the N2K and SeaTalk buses. Started hooking things up and organizing the cabling. Getting there.

In preparation to testing the effectiveness of the new dehumidifier, I want to baseline indoor humidity and temperature in the cabin. Following the plan, I installed the combo sensor from Yacht Devices in the saloon and wired it into the SeaTalk NG bus.