Monty, one of the founding fathers of RailMakers, stopped by today to take measurements for the brand new bow and stern pulpits. The work is likely to take about a month of time but we’ll have awesome new shiny railings. Bonus: we’ll mount the stern running light on them and run wire through one of the bases = one less hole in the hull.

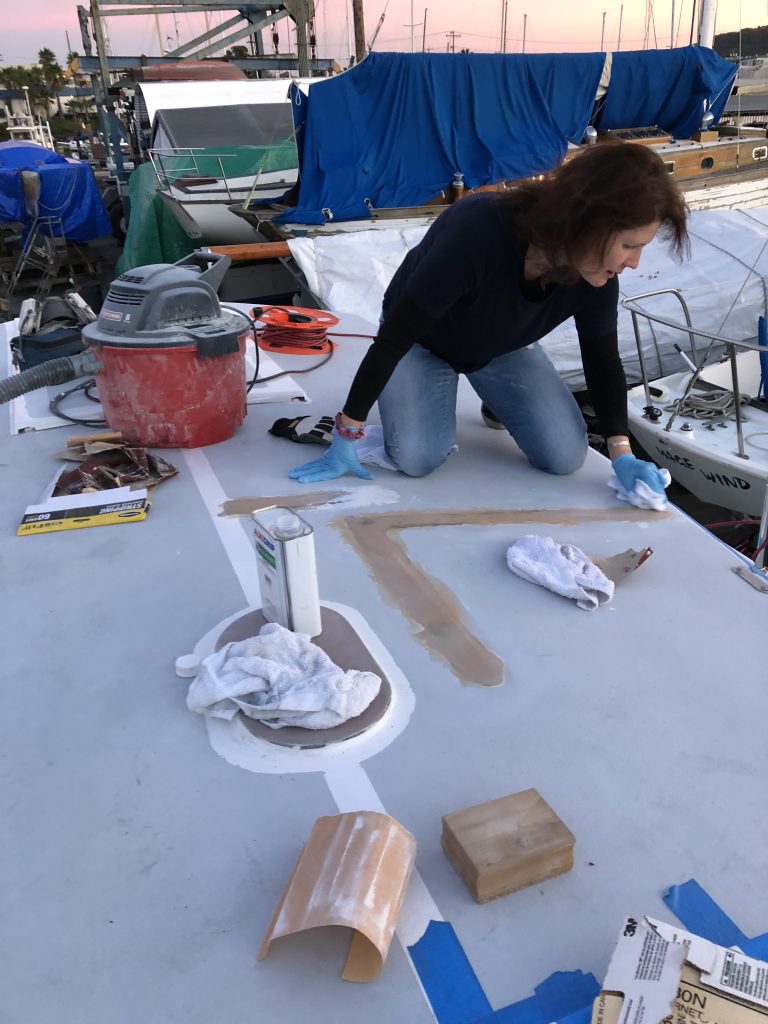

Redo: paint for repaired cracks

Redo: mast base

Redo: cleats

Redo: bow rail holes repair

One of the most painful redos of the project thus far. After removing the bow track, painters plugged holes with some filler. They did such a shitty job that the holes were leaking and paint started cracking. As a quick patch, N put a strip of duct tape to cover them and we left it there for a few weeks. HUGE mistake! Getting that duct tape off took hours. After we were done, we drilled out all the holes, countersunk them from both inside and outside, and filled them properly with epoxy. Solid repair now (albeit requires more paint touch up).