With foam in the saloon, pushed hard this weekend to get dehumidifier installation complete and get interior humidity to mold-unfriendly levels.

First, used the old battery support shelf to make new mounting shelf. Templated with cardboard to fit the curves of the hull and deck drain hoses.

Next, extended the ducts to wrap from port side to starboard. Added inline filters in an accessible place. Used protruding deck hardware bolts to hang ducts closer to the deck and away from potentially being squashed by stuff in the locker (e.g. anchor & rode).

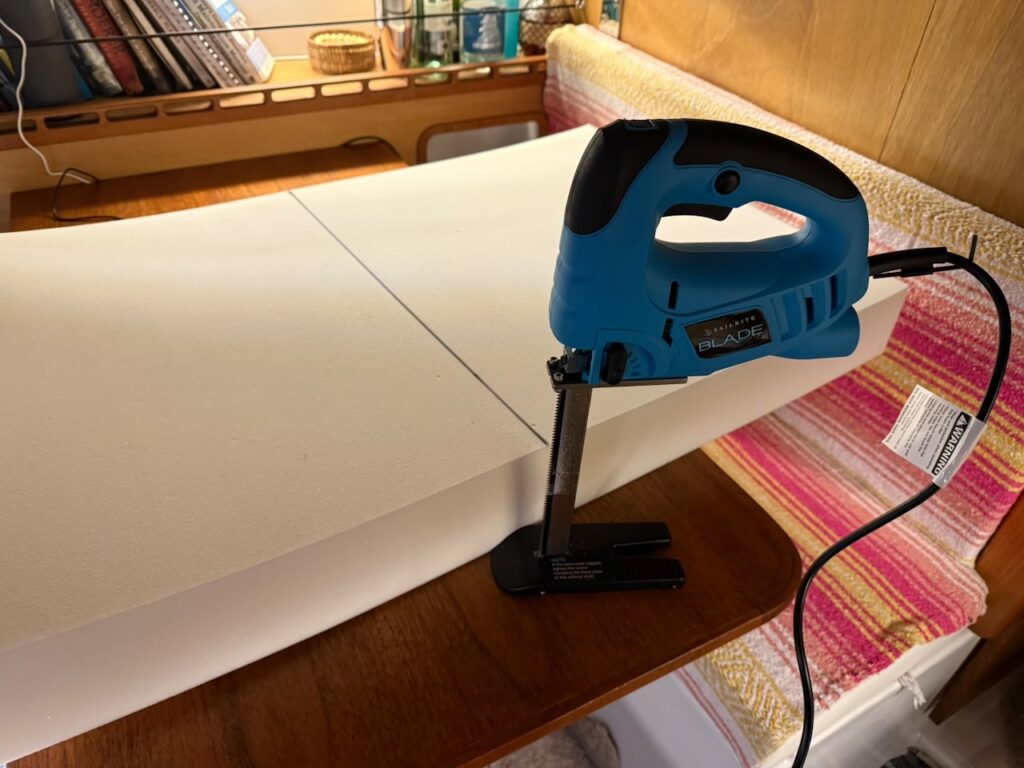

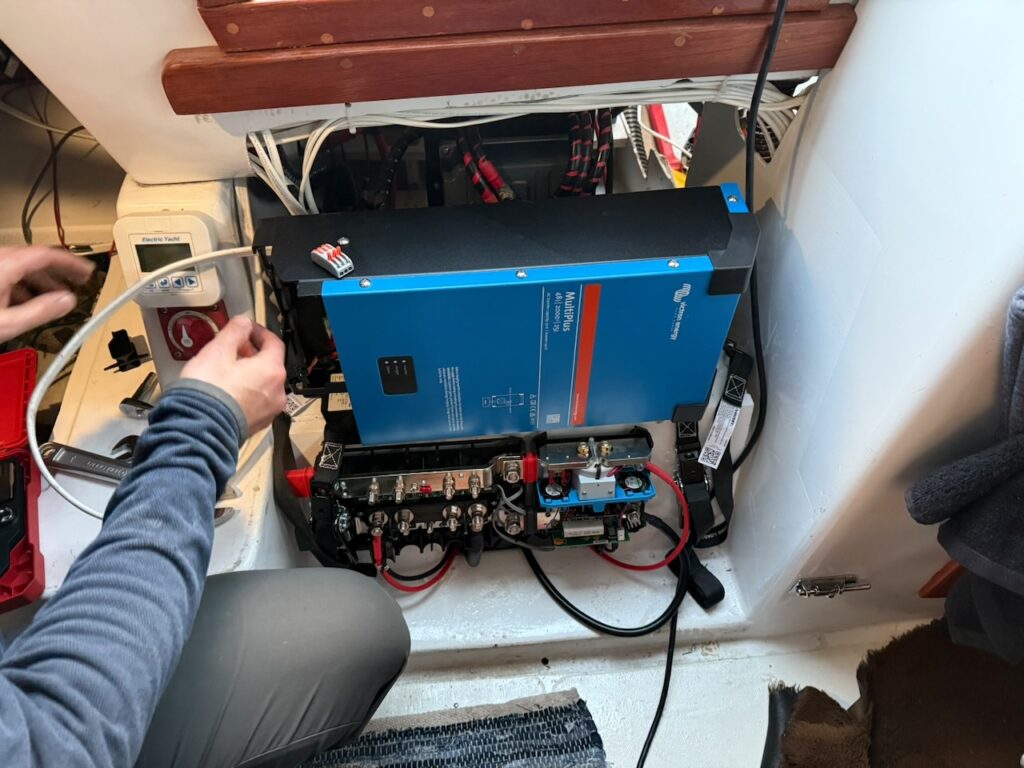

Then, made new back panel for the unit with connectors and flanges that will simplify installation and any needed removal for servicing. My friend Viktar helped get all the connections right.

And finally, mounted the unit and connected intake ducts, cables, and drain hose.

Next on TODO: test operation, strap it down to the shelf, and cover with panels (with vents).