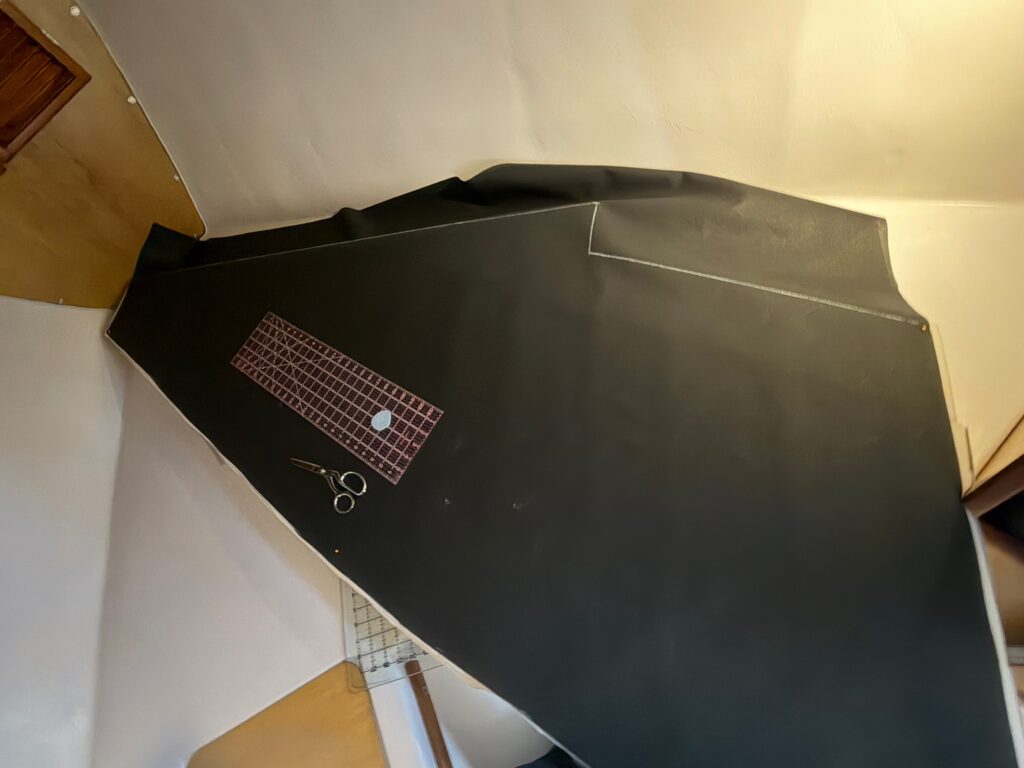

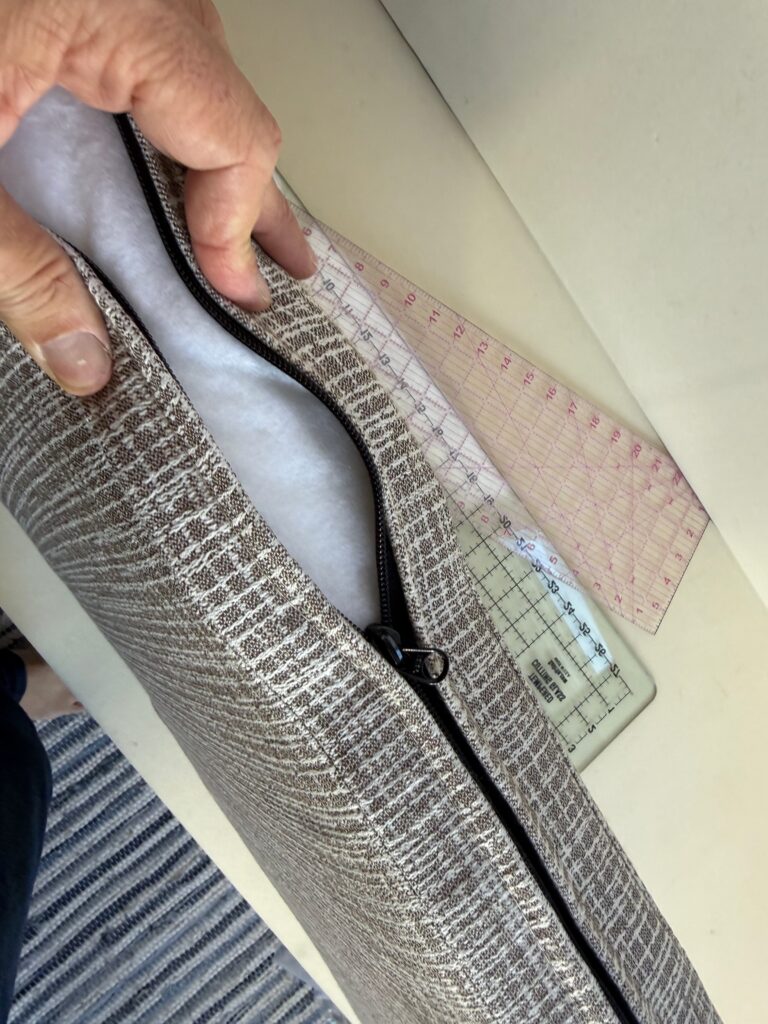

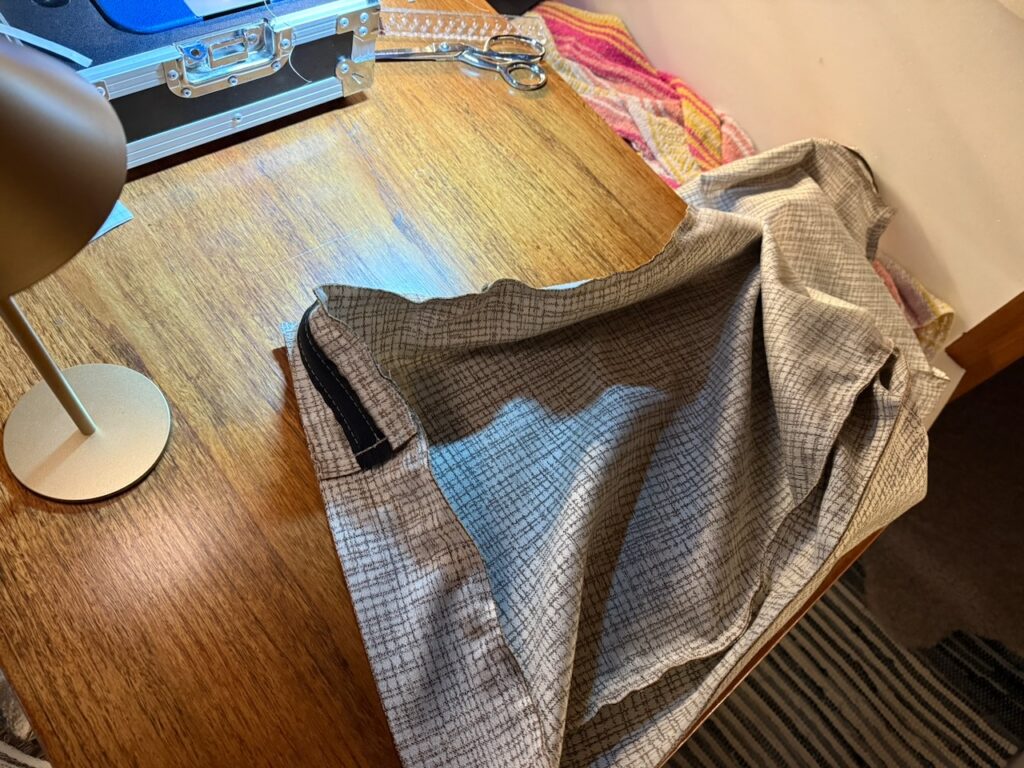

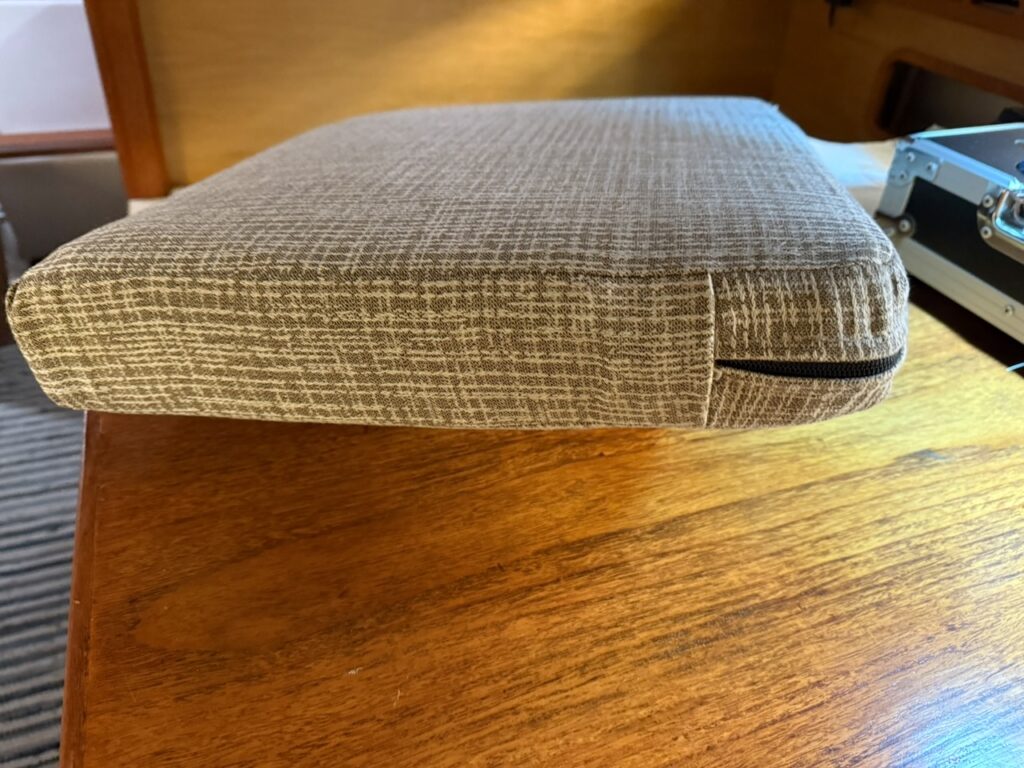

Made one of the cushions for the v-birth today. Ended up being a bit more complex with curve+bevel in one side but turned out OK. Man, the boat doesn’t have much space for this type of work – cushion + roll of material + measuring tools and so for. Spent a lot of time crunched up in tight places.