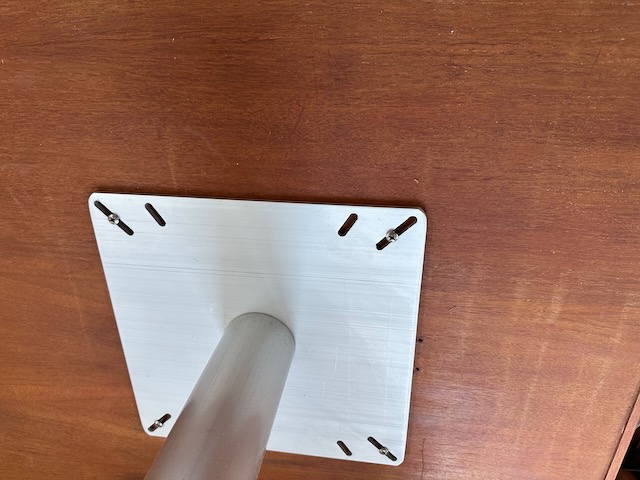

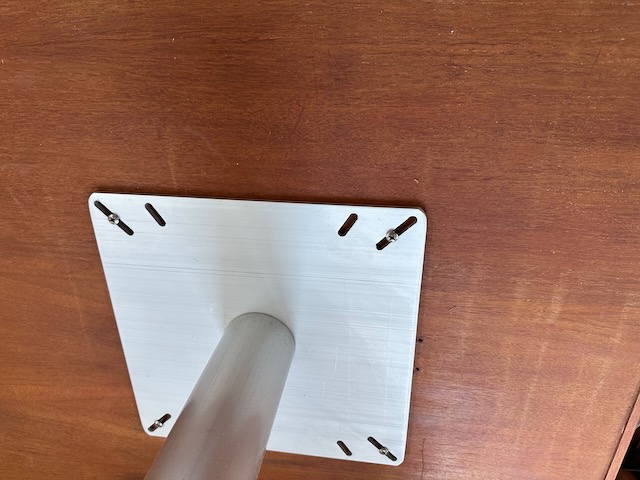

Tested position for the saloon table leg. Not epoxied in yet, just a dry-fit. The teak base needs a bit of adjustment to work with the curvature of the hull before I can glue it in.

1971 Newport 30 Sailboat

Tested position for the saloon table leg. Not epoxied in yet, just a dry-fit. The teak base needs a bit of adjustment to work with the curvature of the hull before I can glue it in.

The span ended up being too wide for 0.5″ plywood so I decided to add a center support piece that would not let the shelves sag. Made it from scrap piece of plywood that ended up matching the needed dimensions and curves pretty well.

After the centerpiece, made and installed the front panel and its trim. Hinges are 4″ off the bottom so that the opened panel will rest on top of cushions (once I make them 🙂

Love the final result. Just need a few latches to keep the door in place.

My original idea to glass in the locker wasn’t good: realized I may need access in the stern area behind it so ideally it would be removable. Adjusted the plan and mounted it with fasteners. Hid 2 of them under the hinges. Also added the drain hose (and new thru hull). Did a dry fit of the lid and added spring to hold it in place. Also did a small cut to make the lock work. Turning out exactly as I envisioned it. Can’t wait to see it painted and finished.

After sides were glassed in, I trimmed excess fiberglass and covered it with epoxy mixed with colloidal silica to smooth things out. Quick makeshift cardboard apron helped keep epoxy from dripping into the boat.

Finally was able to secure 1/2″ Okume plywood to start building the new starboard storage locker/cabinet. Nobody has it anymore, only MacBeath in Berkeley. I used my new nifty tracing tool to get the precise fit to the curve of the hull.

The inner shelf is recessed a bit so that you can access things easier when you open the side panel (to come next weekend). Overall, turning out exactly as I imagined it.

The weather is finally dry and it’s time to undertake the big project of building out propane tank locker to power the galley stove and the fireplace. I couldn’t find any pre-fab hatches that were the right size so this would be 100% custom.

I want to use the part I cutout as the hatch so the cut needs to be super clean and precise. I think I succeeded in that.

Getting the pre-assembled locker in position was a bitch too. Had to take off the rear panel in the quarter birth to have enough room to slip it in. Rough dry fit give an idea of what things will look like.

Whew, this will be a lot of work to get it all done right!