Well, 2025 is a wrap. That was a mixed year for me – making great progress in some areas and dealing with setbacks and blockers in others.

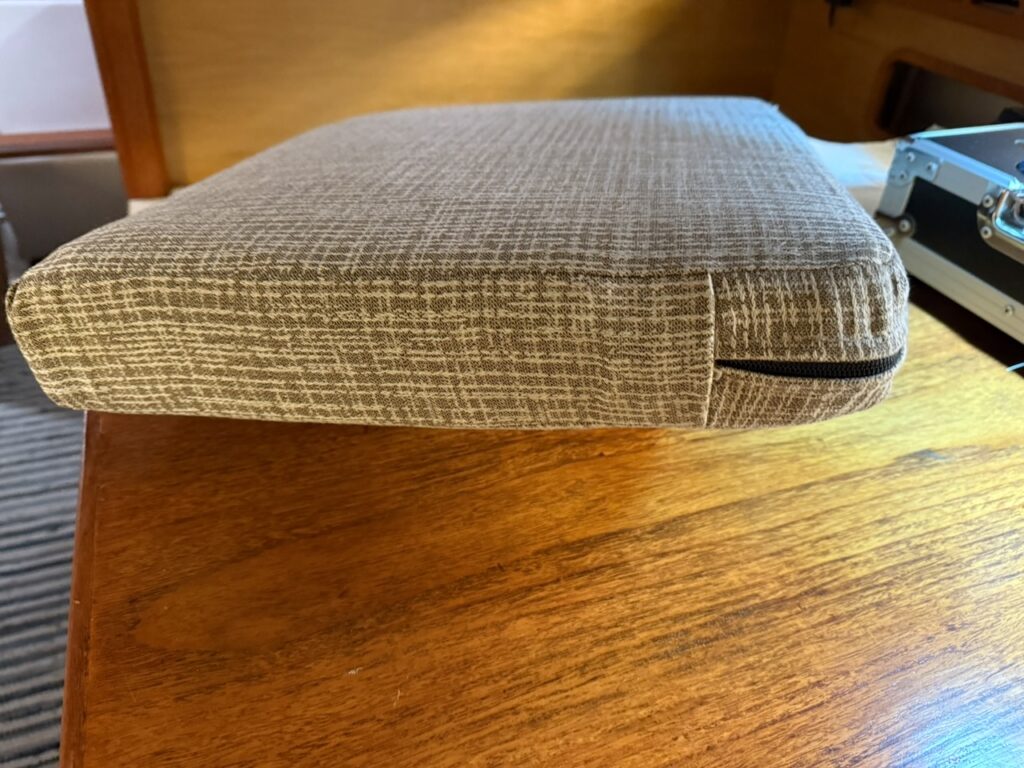

2 of the 3 big projects I wanted to get done in 2025 – upgrade of the propulsion system and electronics – still have some loose ends at the end of the year and will spill over into 2026. The dehumidifier is now in place so at least that undertaking is at 100%. As a cherry on top, I even managed to get started on cushions.

For 2026, the goal is to get the boat to fully sailable and livable state. The ultimate test would be to spend a few days at anchor in Sausalito.

First, I’d love to wrap-up carry overs from 2025:

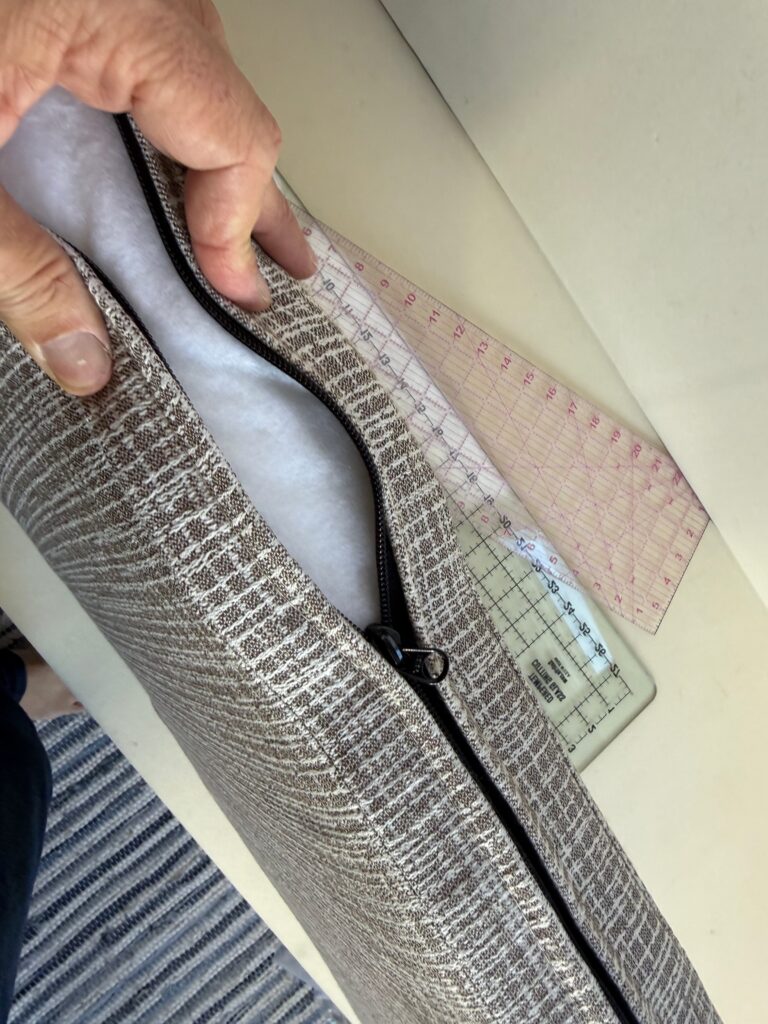

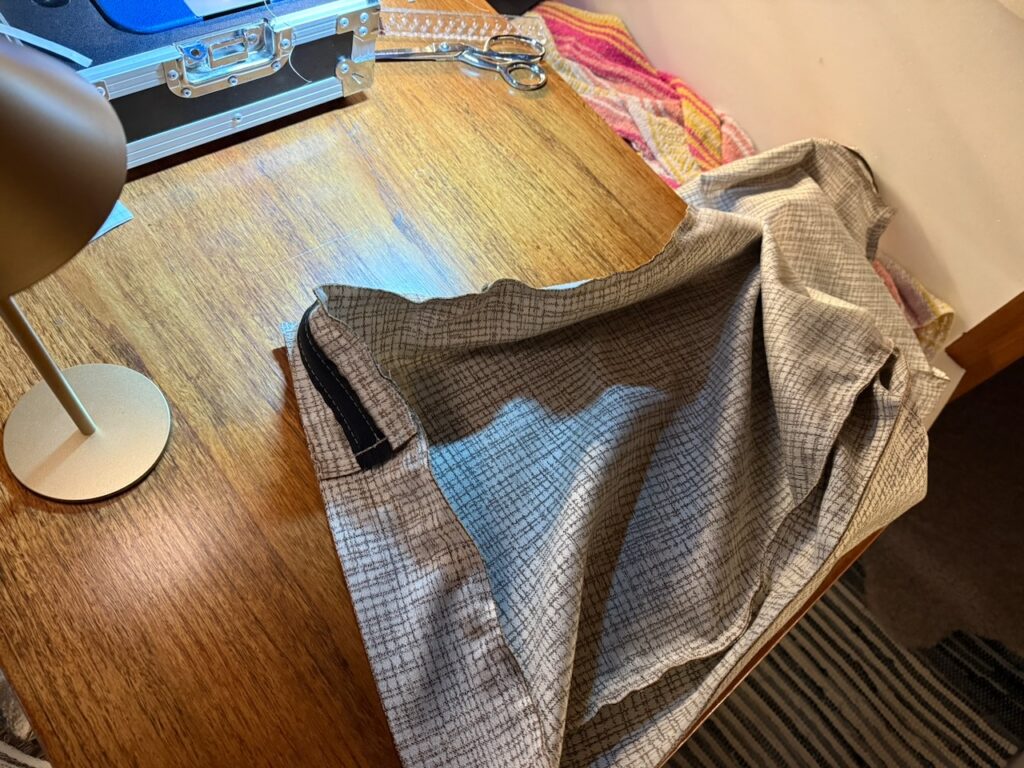

- Finish cushion covers. V-birth and quarter birth are the only remaining to make. For saloon seat backs, I want to make magnetic foam anchors so they stay in place.

- Finalize propulsion system. Fix Lynx BMS and mock with shaft alignment to remove the remaining minor vibrations when underway.

- Finish instruments. Plumb in GPS coordinates from VHS into N2K network and make a custom adapter for QT10 motor into N2K network. Also, rename outside temp & humidity sensors.

Beyond the wrap-up above, here is the new stuff I’d love to get done in the next 12 months:

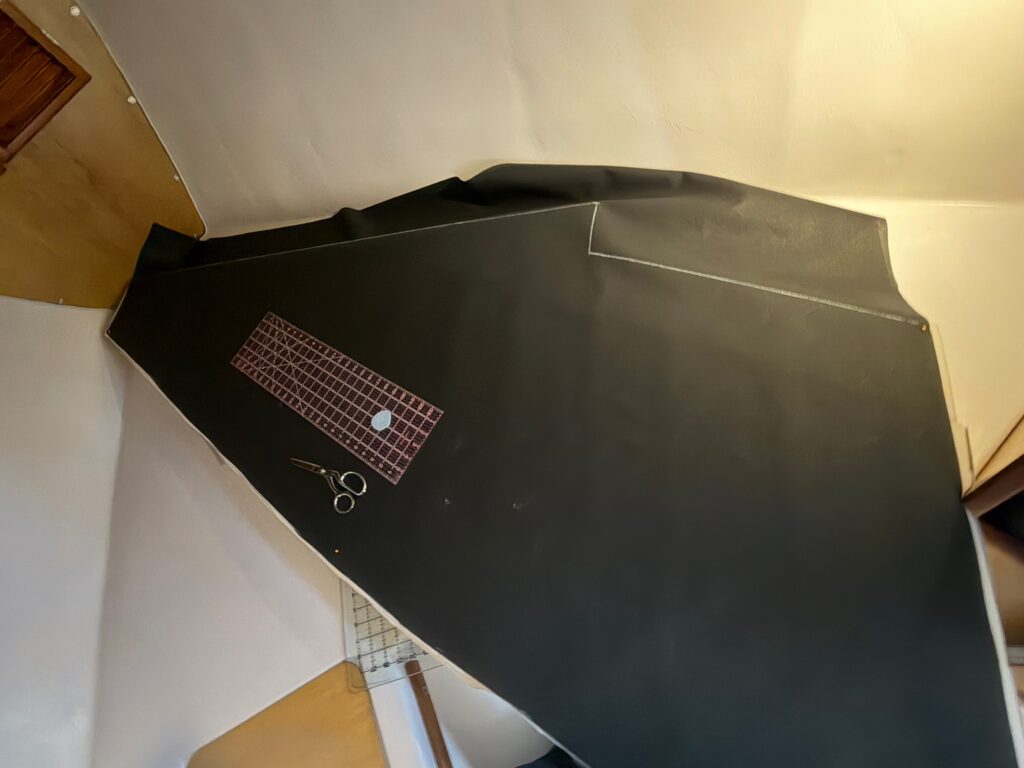

- Install headliner. Already have the material and adhesive.

- Sew pillows using the vintage material that came with the boat

- Organize galley. Add fruit net, put in dividers into drawers, get coffee grinder & other misc kitchenware. Wire fridge into 12V system.

- Finish companionway panels. Add wood trim and lock. Refinish teak.

If all of the above gets done then my original project that started 10 years ago as a “3 months remodel” would be finished. Hard to believe 🙂